What Are the Different Types of Ion Exchange Resins and What Applications Do They Serve?

Ion exchange (IX) is an incredibly versatile technology often utilized in industrial water treatment and selective separation. While all resins generally function on the same basic principles, there is a seemingly endless variety of IX resins available on the market today. Once you understand the basic resin types and their functions, it might be easier to narrow down the right types for your industrial facility and see how they can potentially help to improve your process.

So, “What are the different types of IX resins and what applications do they serve?” This article breaks down available IX resin technologies and describes how they serve a variety of industrial water treatment and separation needs.

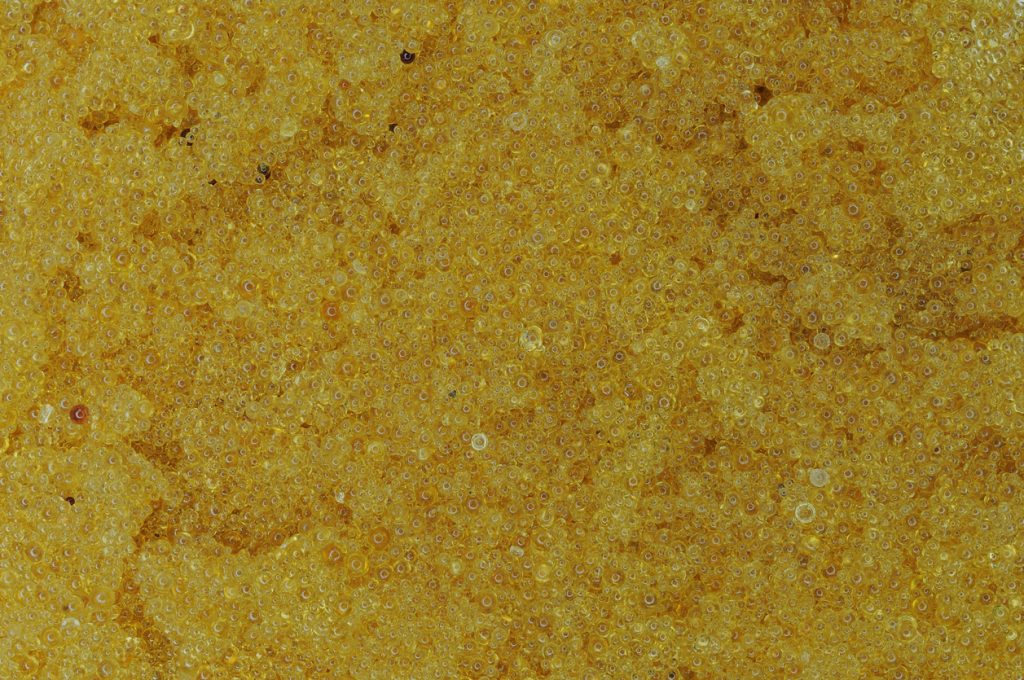

What are ion exchange resins?

IX resins are materials that facilitate IX reactions. They are composed of polymer matrices to which ionic “functional groups” of either positively-charged ions (cations) or negatively-charged ions (anions) are permanently bound. Some specialty resins have both types of functionality. These functional groups have a net negative or positive charge that allows them to readily attract counter ions, or ions of an opposing charge. As a liquid stream flows through the IX resin, the counter ions can be replaced by ions of a similar charge.

Broadly speaking, resins are named for the type of ions they exchange, meaning that cationic resins exchange positively charged ions, while anionic resins exchange negatively charged ions and include:

- Strong acid cation resins

- Weak acid cation resins

- Strong base anion resins

- Weak base anion resins

- Specialty resins

Now that you know the basics, we’ll explore these resins in greater depth below:

Strong acid cation resins

What they are

Strong acid cation (SAC) exchange resins are among the most widely used resins. They are composed of a polymer matrix to which anionic functional groups are bound, such as sulphonate (SO3–). SAC resins are regenerated with either a sodium salt solution (Na2+) for softening applications, or with an acid (H+) for demineralization applications.

What they’re used for

SAC resins are used extensively for softening applications, and are very effective at complete removal of hardness ions such as magnesium (Mg+) or calcium (Ca2+). They may also be used in split-stream dealkalization, where two SAC beds operate in parallel, the first as a softener that produces an alkaline solution, and the second as a demineralizer (in the H+ form), with the result that alkalinity is removed from the blended stream. Certain varieties of SAC resins have also been developed for applications demanding removal of barium and radium from drinking water or other streams. SAC resins can be damaged by oxidants and fouled by iron or manganese, so care must be taken to avoid exposure of the resin to these materials.

Weak acid cation resins

What they are

Weak acid cation (WAC) exchange resins remove cations associated with alkalinity (temporary hardness). WAC resins typically employ carboxylic acid functional groups (RCOO–), and are regenerated with sulphuric or hydrochloric acid. Similar to SAC resins, WAC resins swap cations for hydrogen ions, resulting in slightly greater acidity in the treated stream.

What they’re used for

WAC resins are used for demineralization and dealkalization applications. Their high affinity for divalent cations ions (Ca2+ and Mg2+) makes them a good choice for applications demanding the removal of hardness ions associated with alkalinity. For high temporary hardness applications, a WAC resin can be used ahead of a SAC resin in a two-step IX process. Additionally, WAC resins tend to have relatively high oxidation resistance and mechanical durability, making them a good choice for streams containing oxidants such as hydrogen peroxide and chlorine, among others.

Strong base anion resins

What they are

Strong base anion (SBA) exchange resins are available in multiple varieties, including Type 1, Type 2, and acrylic or macroporous. Each type of SBA resin offers a unique set of benefits and constraints that must be matched to the application at hand.

What they’re used for

SBA resins are typically used for demineralization, dealkalization and desilication, as well as removal of total organic carbon (TOC) or other organics depending on the type of resin. Type 1 SBA resins are used for selective removal of nitrates (NO3-), sulphates (SO3-), and perchlorate (ClO4-), for general demineralization, and for desilication where low levels of silica are required. Type 2 SBA resins are used for applications where total removal of anions is desired, where lower use of caustic is preferred, and where low silica levels are not critical to operational processes.

Weak base anion (WBA) exchange resins

What they are

Weak base anion (WBA) exchange resins are the only major type of IX resins that do not have exchangeable ions. These resins adsorb free mineral acidity (Cl and SO4). WBA resins have amine functional groups, and are typically regenerated with sodium hydroxide (NaOH), ammonia (NH3), or sodium carbonate (Na2CO3).

What they’re used for

WBA resins are used for partial demineralization. In larger plants, WBA resin beds may be paired with SBA units for complete demineralization applications, and WBA resins are also effective as total organic carbon (TOC) barriers ahead of SBA beds. WBA is also used for acid adsorption applications involving the removal of chloride, sulphate, nitrate, and other anions associated with strong acids, though it is not effective for removal of weak acids such as silica (SiO2) and carbon dioxide (CO2).

Specialty resins

What they are

As their name implies, specialty resins are used for a variety of specific applications. Chelating resins are the most common type of specialty resin, and are used for selective removal of certain metals, brine softening and other substances. Specialty resin functional groups vary widely depending upon the application at hand, and may include thiol, iminodiacetic acid, or aminophosphonic acid, and others.

What they’re used for

Chelating resins are used extensively for concentration and removal of metals in dilute solutions, such as Cobalt (Co2+) and Mercury (Hg2+). Another type of specialty resins are magnetic ion exchange (MIEX) resins, which used for removal of natural organic matter from liquid streams.

How SAMCO can help

SAMCO has over 40 years’ experience in identifying appropriate IX resin technologies to help lower costs and waste volumes while increasing product quality. For more information or to get in touch, contact us here to set up a consultation with an engineer or request a quote. We can walk you through the steps for developing the proper solution and realistic cost for your IX treatment system needs.

To learn more about SAMCO’s innovative IX resin solutions, visit our page on ion exchange resin technologies here.

If you want to learn more about ion exchange resins, these other articles might be of interest to you:

- How Much Does It Cost to Buy, Maintain, and Dispose of Ion Exchange Resins?

- Common Problems with Ion Exchange Resins and How to Avoid Them

- What Are the Best (and Cheapest) Ways to Dispose of Ion Exchange Resins?

- What is the Difference Between Cation and Anion Exchange Resins?

- What to Know About Ion Exchange Resin Regeneration

- What Are the Best Ion Exchange Resin Manufacturing and Supply Companies?

- What Is Ion Exchange Resin and How Does It Work?