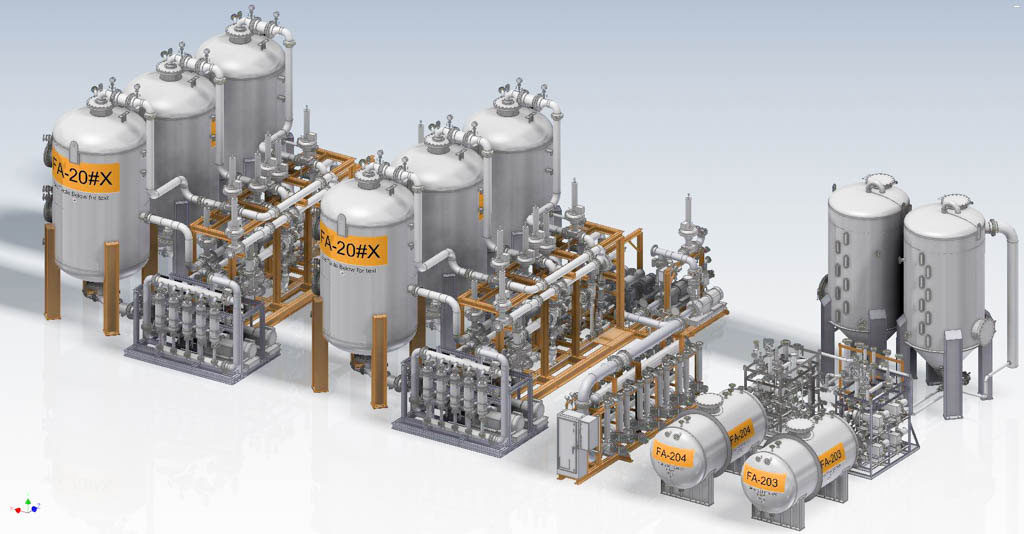

AMBERPACK Sandwich Polishing System

The AMBERPACK SANDWICH™ polishing system is a unique system that uses anion and cation resins that are separated by a nozzle plate and situated in a dual chamber configuration. With the capacity to hold twice the amount of resin that a mixed bed system can, and with a much smaller footprint, this efficient polishing system can produce a high-quality fluid stream comparable to a traditional mixed bed system, while occupying half the space. Ideal for treating low-salinity water, this polishing system also eliminates cross-contamination because the resins are not mixed, and the frequency of regeneration is reduced.

Advantages:

-

-

- Smaller footprint

- Efficient removal of sodium and silica

- Little water consumed during generation

- Can use 2 or 3 chambers (cation, anion, cation for higher quality)

- Lower sodium leakages

- Can handle high variations in feedwater chemistry

- Proven, long operating history

-

Disadvantages:

-

-

- Must be filtered to low particles prior

- Chemical feed storage tanks and chemicals required

- Neutralization process required

-