What Are the New Steam Electric Power Generating Effluent Guidelines and What Do They Mean for Your Plant?

The recent updates to the U.S. Environmental Protection Agency’s (EPA) Steam Electric Power Generating Effluent Guidelines (also known as effluent limitation guidelines or ELGs) for steam electric power plants mean significant updates for most plants involved. Since the EPA circulated the first round of regulations in 1974 with the last changes made in 1982, the final rulings signed into action last November will be the first in over 30 years.

After careful evaluation, a lengthy study, and thorough laboratory testing of flue gas desulfurization wastewater over a time span of 10 years, the EPA decided that the current regulations weren’t up to date with newer effluent characterizations and that greater limitations needed to be placed on the level of toxic materials that could be disposed of, with much of the emphasis on eliminating dissolved toxins and including other regulations aimed at reducing the amount of water a power plant can consume from its source.

Although the final ruling was signed into action at the end of last year, there’s still time to be sure your plant is up to code, but the time to act should really be now. With less than three years to meet these revised guidelines, strictly managing discharge into surface water or publicly owned treatment works (POTW) and reducing your process water intake according to these new guidelines will likely require your plant to develop a plan of action and make some technological upgrades to your process.

Here are a few questions you might be wondering:

Who do these ELG changes affect?

Basically, if you’re a steam electric power plant in the United States that operates as a utility; uses nuclear or fossil fuels (such as coal, oil, or natural gas) to heat water and generate steam to power your turbines; and discharges waste either “directly” into the environment under a National Pollutant Discharge Elimination System (NPDES) permit or “indirectly” into a POTW, your plant will likely be required to comply.

A good estimation of power plants that will be included are those that fall under NAICS codes 221112 (fossil fuel electric power generation) and 221113 (nuclear electric power generation). Although these NAICS codes can be used as a general guide as to which plants will be required to comply, make sure you’re aware of the full list of applicable factors provided by the EPA for a more detailed definition (see 40 CFR Part 423).

Why is the EPA implementing these new ELG regulations?

According to the EPA, the majority of steam electric power plant wastewaters that result from water treatment, power cycle, ash handling, and air pollution control systems come in the form of chemical and thermal pollutants. Other pollutant sources include coal piles, yard and floor drainage, among other types of waste. The harmful toxins include arsenic, lead, mercury, selenium, chromium, and cadmium, and can remain in the environment where they are discharged for years.

While the old regulations required these plants to eliminate many of these toxic particulates by settling, the EPA found that there wasn’t enough regulation placed on the amount of these toxins allowed in the waste when dissolved.

If left unchecked, and depending on whether they’re discharged into an open body of water or POTW, these pollutants can contaminate drinking water sources and can cause health problems in humans and environmental pollution affecting fish and wildlife.

The EPA estimates that these new effluent guidelines will reduce the level of these toxins from being discharged by 1.4 billion pounds, in addition to reducing the amount of water these plants can withdraw by 57 billion gallons, each year.

What type of updates to your power plant will you be required to make?

All in all, the regulations are technology-based updates, meaning the changes you’ll need to make at your plant in order to comply with the new ELG regulations have been decided upon by the EPA based on the level of purity achievable by the technology recommended by the agency.

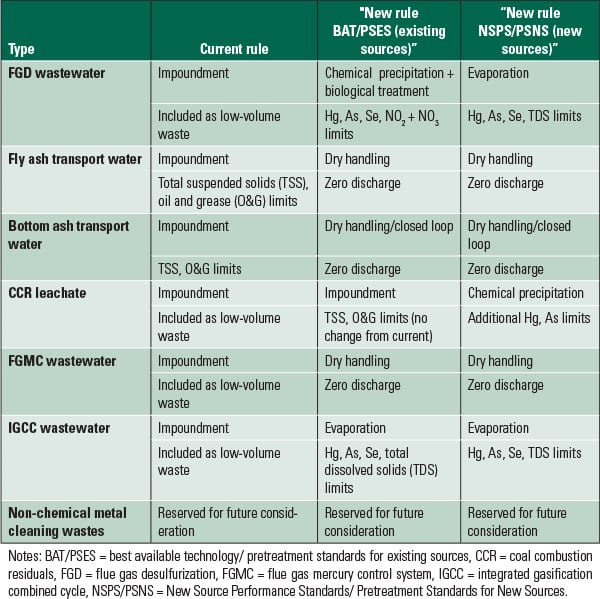

In addition to nonchemical metal cleaning wastes, which are being held for further consideration in the future, the ELG updates focus on six main power plant wastewater streams outlined below:

- Flue gas desulfurization (FGD) wastewater

- Fly ash transport waters

- Bottom ash transport waters

- Coal combustion residual (CCR) leachate from landfills and surface impoundments

- Wastewater from flue gas mercury control (FGMC) systems

- Integrated gasification combined-cycle (IGCC) wastewater

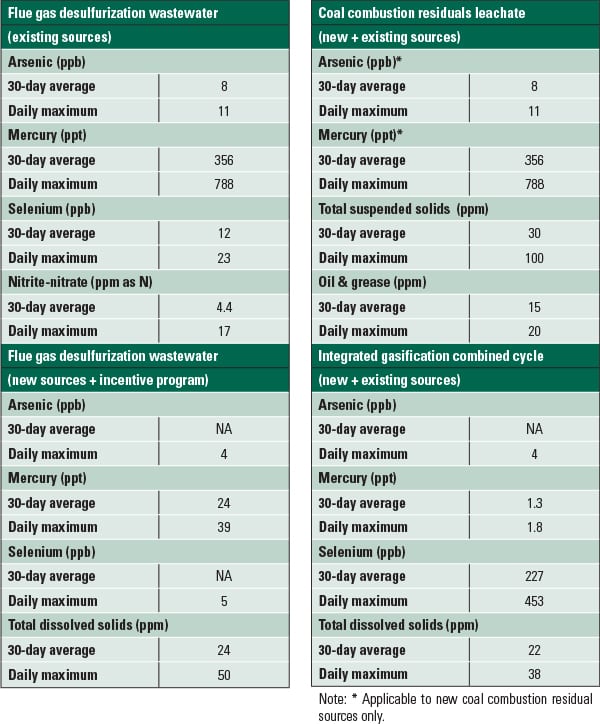

Here are two useful tables/summaries of the new ELG technology basis and limitations in comparison to the old rules and important numerical limitations:

Table source: HDR Inc. via Power Magazine

When do affected power plants need to finalize these updates?

The EPA requires all plants to comply with the new ELG regulations with NPDES permit renewals between November 1, 2018, and no later than December 31, 2023.

Your plant’s compliance timeline will depend on whether or not you discharge your wastewater to a surface water or POTW and will be set by your plant’s permitting authority who will determine the appropriate timeline for planning, designing, engineering, and installing the new equipment, among other factors as needed.

There is a time extension or voluntary incentive program for plants that agree to use vapor compression evaporation systems for FGD wastewater treatment. This option might be particularly beneficial for power plants upstream of drinking water sources with stringent TDS limitations.

What should your next steps be to comply with these ELG standards?

Now that you know the requirements, what should your next steps be? We recommend that you:

- Examine all regulatory specifications ruled by the EPA carefully to be sure you understand what your plant needs to achieve in order to comply.

- Explore cost-effective recycle and reuse technologies for your waste, particularly for FGD and low-volume waste.

- Consider treatability testing for your wastewater.

- Evaluate your plant’s current water/wastewater characteristics.

- Develop a plan and start the process of evaluating the different companies and solutions that can help you comply.

- Minimize the amount of water in your facility by going to waterless systems like dry FGD and FGMC process, and use conveyance system that are dry based.

- Carefully consider the implications of a new waste source stream in the facility and the regulatory implications.

- Carefully consider technologies to be selected as part of any treatment for CCR landfills, leachate lagoons, and containment ponds/closures. Treatability and pilot studies might help, and using temporary equipment and/or rental equipment is an option for short-term closure activities.

How SAMCO Technologies can help you implement a custom-engineered solution to meet the new ELG standards

SAMCO Technologies has provided custom water, wastewater, process separation, and filtration solutions to a diverse range of industries for over 40 years, and all our systems are designed to be integrated into larger systems or process trains.

This integration capability is important when new equipment will be added to an existing system’s control schemes. It is also important when developing an entirely new process train or system for future add-on capabilities and can be extremely beneficial to your plant when trying to integrate these new technologies into your existing system.

SAMCO can work with you and your consultant to evaluate your overall stream flow and mass balance and develop a short and long treatment strategy. We can further support this program with treatability and pilot optimization studies. SAMCO has a fleet of rental equipment and site operations to asset cost effectively in the program execution.

If you have questions about these new regulations and would like to speak with one of our engineers about your options and how our services might help, contact us here or visit our service section on our website to learn more about what we offer.

Some other articles about wastewater treatment systems you might be interested in include:

- What is a Wastewater Treatment System and How Does it Work?

- How Do You Know If An Industrial Facility Needs a Wastewater Treatment System?

- How to Choose the Best Wastewater Treatment System for Your Plant

- Seven Ways Your Facility Isn’t Meeting Effluent Regulations and How to Solve Them

- The Importance of Wastewater Treatment for Your Facility: Is it Necessary?

- 9 of the Best Industrial Wastewater Treatment Equipment Supply and Technology Companies

- What Is a Wastewater Treatability Study and How Does it Work?

- How Much Does a Water/Wastewater Treatability Study Cost for Your Plant?

- How Much Does a Wastewater Treatment System Cost? (Pricing, Factors, Etc.)