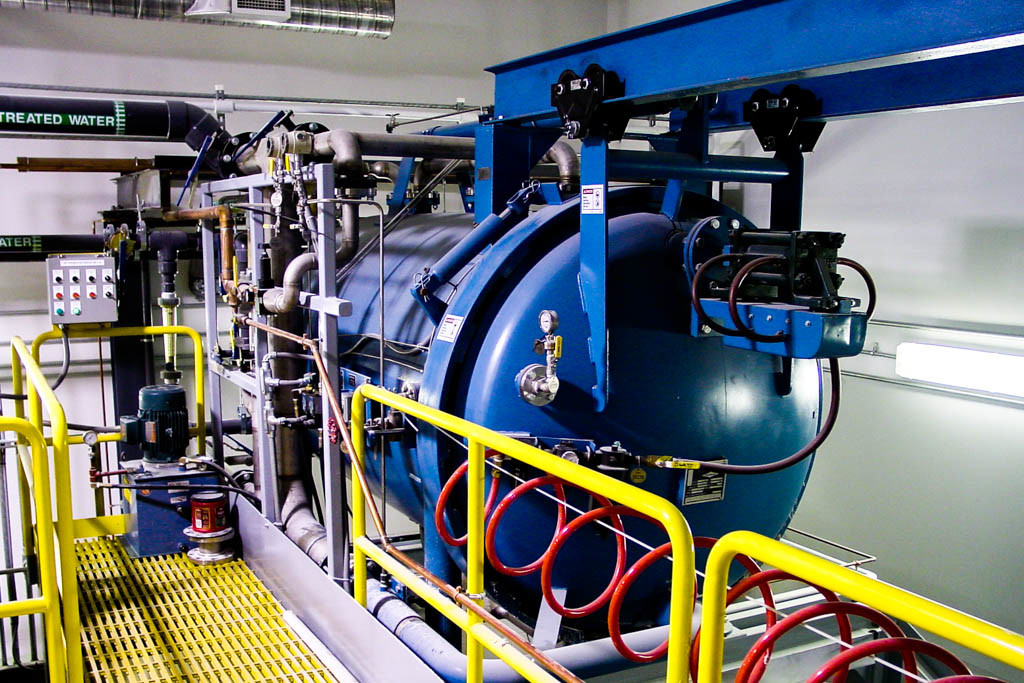

Pressure Leaf

SAMCO pressure leaf filters (PLF) use internal filter leafs that provide submicron particulate removal. They are designed specifically for high flow rates and can be configured for dry cake or sluice discharge and cleaning efficiency.

Pressure leaf filters are often used in the following industries:

-

-

- Brewery & Spirits

- Tallow & Edible Oils

- Sulfuric Acid Production

- Pharmaceuticals & Cosmetics

- Plating Bath Recycle

- Brine Polishing

- Sugars & Sweeteners

- Mining & Minerals

- Chemical Processing

-

Advantages:

-

-

- Reduces volume of sludge disposal

- Can be effective for zero liquid discharge (ZLD)

-

Disadvantages:

-

-

- Increases capital cost

- Large footprint

-

Our PLF solutions can help you with your separation and filtration needs.