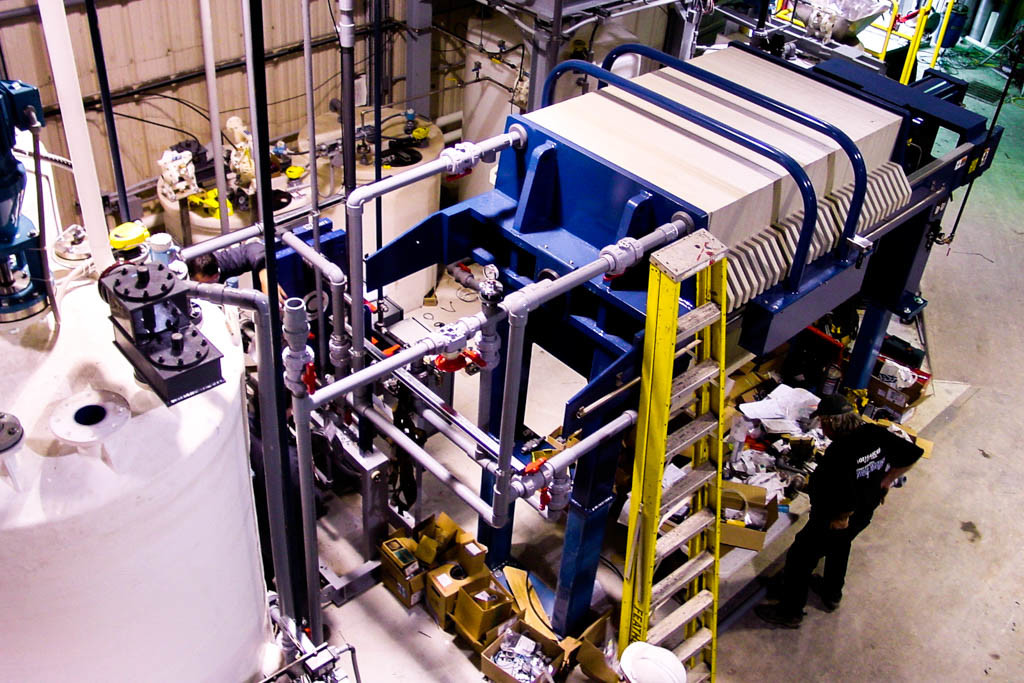

Filter Press

SAMCO’s filter presses (FPS) are one of the most effective ways to dewater and compact liquid slurry. Our FPS are typically capable of dewatering up to 30%–60% of the solids, producing clear filtrates while separated solids are removed from the press as a single, disposable cake.

Our filters utilize recessed chamber plates that are concave on both sides and covered with a cloth filtration media. They are held together under pressure by a press frame and hydraulic system to create discreet filtration and solid holding chambers within the press.

Liquid slurry is pumped into the press and fills these chambers, where the liquid and solids separate (dewater) via the pressure from the feed pump. Filtered liquid then passes through the filter cloth media and continues out of the press while solids are collected and concentrated in the recessed chambers.

Advantages:

-

-

- Reduces volume of sludge disposal

- Can be effective for zero liquid discharge (ZLD)

-

Disadvantages:

-

-

- Increases capital cost

- Large footprint

-

Our FPS technology is the right solution for you.