Tube Filtration

SAMCO’s tubular backwash systems (TBS) are used in a host of applications for the removal of particulates from liquid streams. Various filtration materials are used, depending on the specifics of a given application. Individual tubes are available in a range of sizes and materials of construction that can be customized based on your individual needs.

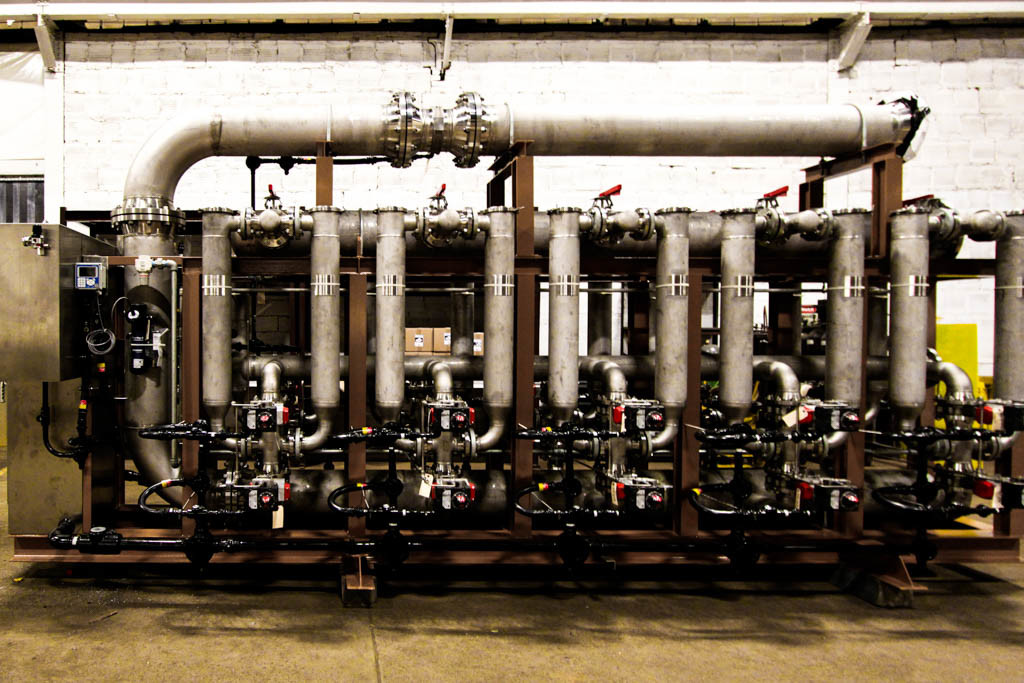

Single tube units are often used for batch processes. However, by periodically backwashing a filter element with a clean liquid, a TBS element can be regenerated in place. TBSs can also be used in continuous flow applications by using multiple tubes that are arranged in manifold to form a system. When a predetermined differential pressure or amount of time is reached, each tube is isolated by valves and backwashed individually, thus allowing for reuse even when a continuous filtered liquid flow is required.

Internal backwash systems use a portion of the filtered liquid as the backwash supply. If the filtered liquid is not desirable to use in this capacity, an external backwash design can be specified allowing for an alternate backwash supply source to be used.

SAMCO TBS can help you conserve valuable product, protect your downstream equipment, improve your production process and efficiency, and do so with minimal operator attention.

Advantages:

-

-

- Efficient particulate removal and polishing

- Small footprint (1/10th the size of conventional sand and multimedia filters)

- Backwash is small compared to sand and multimedia filters

- Various types of pore selections (from 1,000 microns down to 1)

- Come in several materials

-

Disadvantages:

-

-

- Used as a polishing filter and doesn’t take out large volumes of suspended solids

- Not effective with sticky, gelatinous material

-

SAMCO’s engineers can suggest a high-performance, high-volume TBS that’s right for you.