Technologies and Innovations

Physical Chemical

With innovative technologies that can help you remove contaminants both large and small, SAMCO can help you protect your equipment and meet stringent discharge regulations our highly customized treatment systems.

Raw Water Clarification

Lime Softening

Reverse Osmosis-Nanofiltration

Here at SAMCO, we understand that your filtration needs can vary depending on particle shape, size, and physical attributes. Armed with a wide assortment of filter configurations, let our engineers help you determine the best way to remove those particles—no matter what end of the process that needs to be addressed.

High Efficiency Reverse Osmosis (HEROTM)

Resin

At SAMCO, some of our most innovative solutions come in the form of the various resin technologies we offer. When it comes to selectively removing unwanted dissolved ions or anions from fluid streams, resins can be extremely effective in the removal of hardness, alkalinity, chloride, mercury, and organics, to name a few.

UPCORE Ion Exchange

Ion Exchange Softening

Advanced Amberpack ADI

Specialty Ion Exchange

Biological

Does your facility produce organic-heavy waste? Biological wastewater treatment solutions might be what your plant needs to transform difficult-to-treat, high-BOD waste into cleaner effluent that’s easier to manage. Whether your facility discharges to a municipal sewer or back to the environment, removing organic substances from water and air can be challenging.

Fixed Bed Bioreactors-FBBR

Membrane Bioreactor-MBR

Moving Bed Bioreactor (MBBR)

Biological Trickling Filter

Brine Lithium Softening Recovery Purification

SAMCO uses various proprietary resins to separate contaminants, such as metals, from the brine stream to allow for production and manufacturing of lithium carbonate and lithium hydroxide. We have strong expertise in this area with hundreds of projects completed and can evaluate your brine stream and selectively apply the right combination of custom technologies to treat your stream.

Sulfate Removal

SAMCO’s sulfate removal process is a membrane process that is used to take out sulfates from the ocean water and/or brine streams. When sulfates are present in crude oil, the bacteria eat the sulfates and break them down into hydrogen sulfide gas. SAMCO can help you efficiently remove these sulfates so the biological activity doesn’t take place.

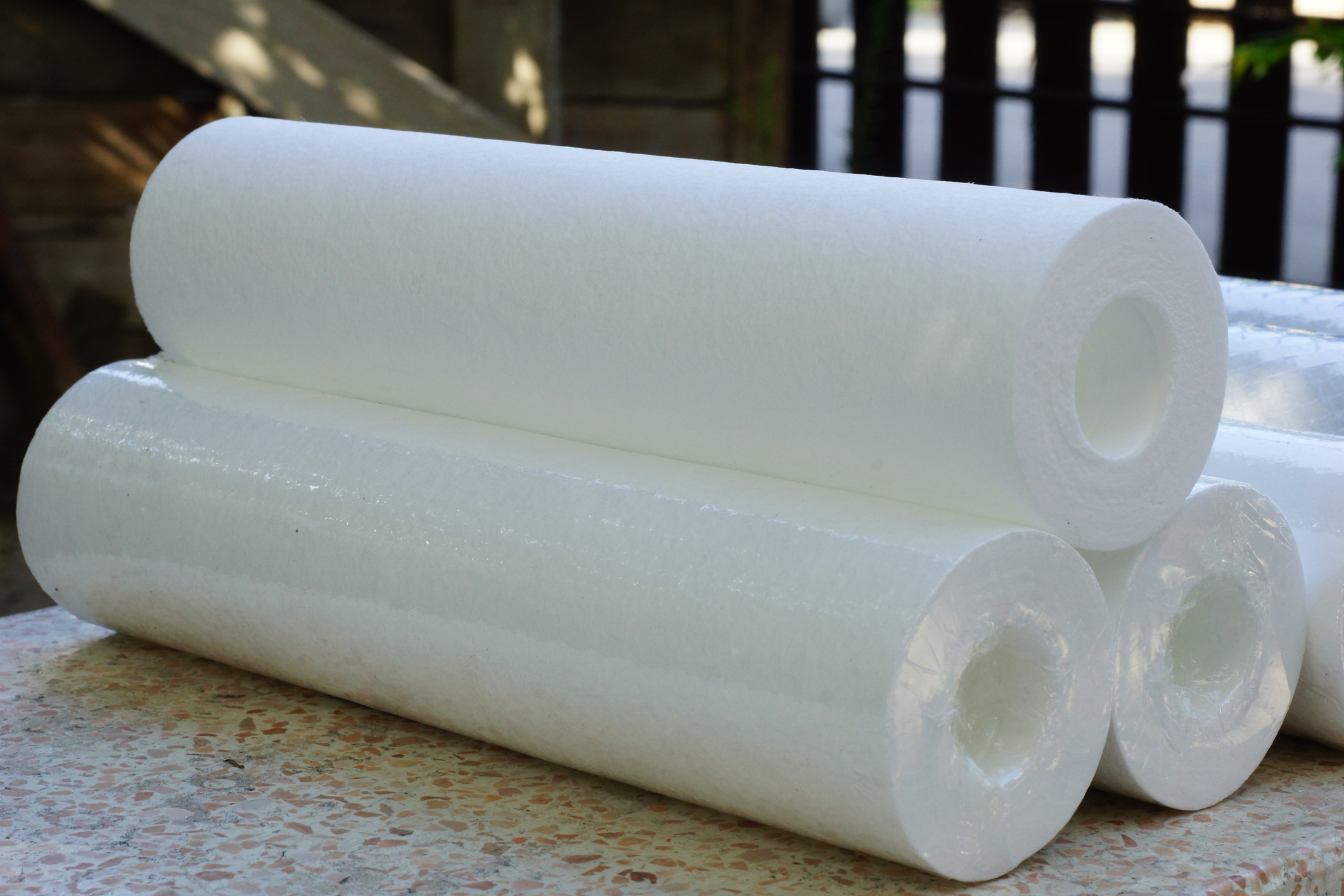

Filtration

Here at SAMCO, we understand that your filtration needs can vary depending on particle shape, size, and physical attributes. Armed with a wide assortment of filter configurations, let our engineers help you determine the best way to remove those particles—no matter what end of the process that needs to be addressed.

Sand Filtration

Cartridge Filtration

Pressure Leaf

Hydra-Shoc

Carbon Filtration

Tube Filtration

Filter Press

Microfiltration-Ultrafiltration

SAMCO’s microfiltration (MF) and ultrafiltration (UF) technologies efficiently handle a range of turbidities and densities of feedwater down to sub-micron levels. Our MF/UF technologies have helped some of our customers reduce the amount of pathogens and certain types of bacteria and viruses (including Giardia cysts), improve silt density index (SDI), reduce colloidal silica, or sterilize fluids for drinking.

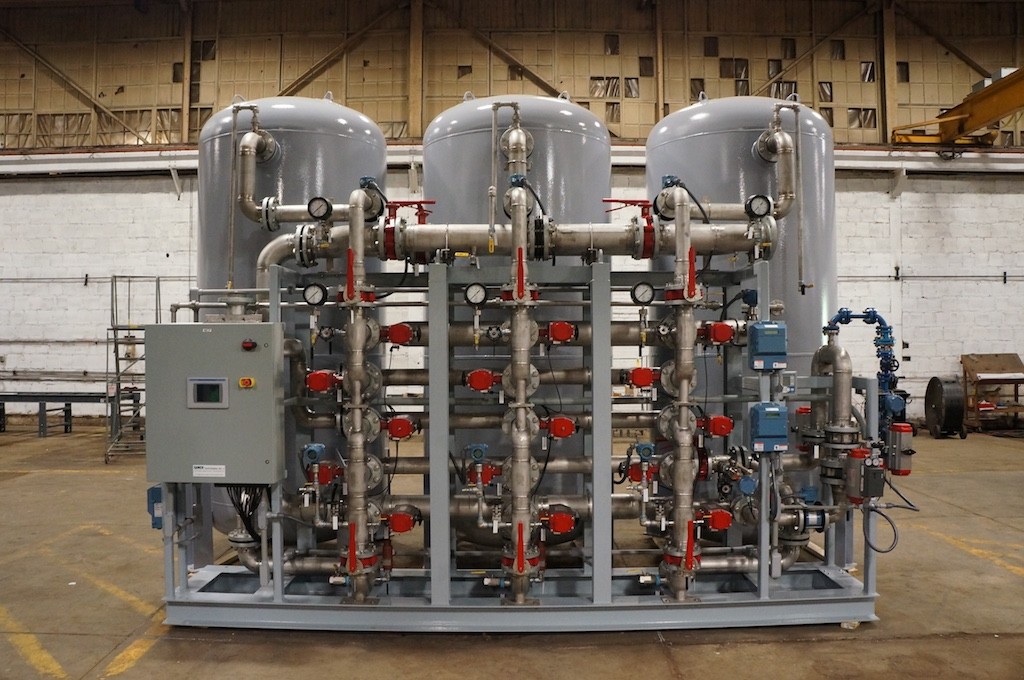

Polishing

Most industrial water applications require polishing downstream of primary ion exchangers or reverse osmosis—especially for boiler feed water or any process that requires extremely high-purity water. Over the years, SAMCO has installed and serviced hundreds of integrated polishing systems that have reduced both suspended and dissolved solids to ultrapure levels.

Mixed Bed Ion Exchange Polishing

AMBERPACK Sandwich Polishing System

Twin Bed Ion Exchange Polishing

Electrodeionization (EDI)

Platform Oil and Gas Recovery

With advancements in deep ocean exploration, oil and gas continue to be inventively harvested around the world, and SAMCO has developed a range of solutions that can assist your company with efficient processes that are just as innovative.

Sour/Natural Gas Separation

Desalting Water Preparation

Phenols Removal from Wastewater

Produced Water Treatment and Recovery

Two-step Oxygen Removal

Rare Earth Metals Recovery

SAMCO has plenty of expertise in applying membranes and various types of resins and chemical processes to separate out rare earth metals, such as cadmium, indium, and rhenium. Contact us to set up an immediate call with one of our engineers and see if our rare earth metals recovery innovations can help meet your needs.

SAMCO Licensed Technologies

SAMCO is proud to offer a diverse range of licensed technologies that can be applied to your purification and separation requirements. Offering the highest quality technologies to suit our customers’ needs is our number one priority.