Project Briefs:

Power Plant Secures Rapid PCB Removal Compliance and Efficient Flow Management SAMCO Groundwater Treatment Solution

Project Overview

Objective

Remove PCBs from contaminated quarry discharge streams to meet stringent New York State Department of Environmental Conservation (NYSDEC) and United States Environmental Protection Agency (US EPA) regulatory requirements of <60 parts per trillion (ppt).

Scope of Service

SAMCO performed all design, engineering, fabrication, installation, and ongoing operations and maintenance support for a comprehensive fast-track solution, consisting of a permanent wastewater treatment plant and supplementary trailer- mounted system for peak flow management.

Challenges

- Seasonal flow rate variability

- Stringent discharge specifications

- Tight compliance deadline

Solution

SAMCO designed and delivered a 100 GPM waste water treatment plant with proprietary contact clarification pretreatment components for removal of both particulate and dissolved PCBs from quarry waste water. The prepackaged design allowed the client to meet critical compliance deadlines, while an included supplementary trailer-mounted system allowed for efficient scalability to accommodate seasonal peak flows of 400 GPM. The turnkey design also included a SCADA-integrated programmable logic controller (PLC) system to both minimize manual operational demands and produce automated regulatory reports measuring flow, level, pressure, pH, and other process monitoring data.

Technology

Deliverables comprised a prepackaged treatment plant. Key components included:

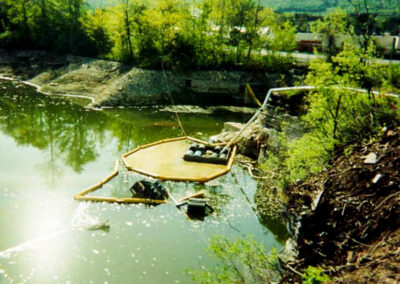

- Floating pump station

- Pressurized reactor

- Equalization tank

- Contact clarifier

- Multimedia & activated carbon filters

- PLC and remote telemetry controls