Project Briefs:

Pharmaceutical Company Upgrades their Ultrapure System for Higher-Quality Water and Increased Efficiency

Project Overview

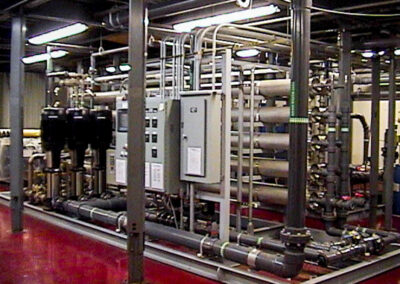

At a leading high-definition display device manufacturing facility in New York, SAMCO worked with the client to create an ultrapure water system designed to purify the client’s city water to meet high-quality standards of the microelectronics industry and recycle wastewater for reuse.

Objective

Purify the client’s city water to 0.5+ meg-ohm/cm high-purity water.

Scope of Service

An effective solution comprised detailed design/engineering; controls integration; system fabrication; field installation support; commission, startup, and training; and ongoing maintenance and system support.

Challenges

- Wastewater recycle/reuse capability

- Critical application requiring 99% uptime

- Fast-track project, concept to completion

Solution

Technology

Project deliverables and equipment included:

- RO system and holding tank

- Antiscalant/bisulfate feeds

- Bag pre-filters and UV sterilizer

- Distribution pumps

- Stainless steel RO pressure vessels and cartridge filters

- PLC controls with remote telemetry