How Much Will a Zero Liquid Discharge System Cost Your Facility?

With increasing stewardship of environmental protection, both nationally and internationally, many industrial facilities and effluent regulators are strengthening strategies to reduce industrial process waste by implementing zero liquid discharge (ZLD), a process that limits liquid waste at the end of your industrial process to—as the term suggests—zero.

A more recent example of how ZLD is being recommended for tightening effluent regulations is the new mandates passed by the U.S. Environmental Protection Agency for steam electric power plants, with new rules for limiting harmful pollutants point to ZLD as the primary solution for treating fly ash transport water, bottom ash transport water, and flue gas mercury control system wastewater.

It can be challenging to find a system for your facility that is both environmentally friendly and cost effective, especially when more and more effluent regulations are tightening and dwindling your discharge options.

If your facility’s goal is to eliminate discharging these pollutants that normally flow into deep wells, streams, sewers to publicly owned treatment works (POTWs), and other waterways, ZLD might be a good fit. Just keep in mind that, realistically, ZLD often only makes economic and environmental sense when there are certain criteria. For example, if the facility is in an area with no sewers and can’t, by regulation, discharge its waste to the environment, ZLD might be beneficial, treating the water to eliminate liquid waste. Sometimes facilities want to recycle or recover valuable materials in their wastewater. ZLD or near-ZLD technology can benefit facilities like this, too.

If you are thinking your facility might require ZLD technology, you might also be wondering how much does a ZLD treatment system cost and what are the factors that affect that cost? This article breaks the answer to this question down for you below:

What’s included in a basic ZLD system?

The specific technologies that will make up a facility’s treatment system will vary greatly depending on (1.) the volume of dissolved material present in the waste, (2.) the system’s required flow rate, and (3.) what specific contaminants are present. The required technologies will also affect the system’s cost.

Despite the possible variations that depend on your facilities wastewater characterization, a ZLD system is generally a three-step process consisting of the following “blocks” of treatment:

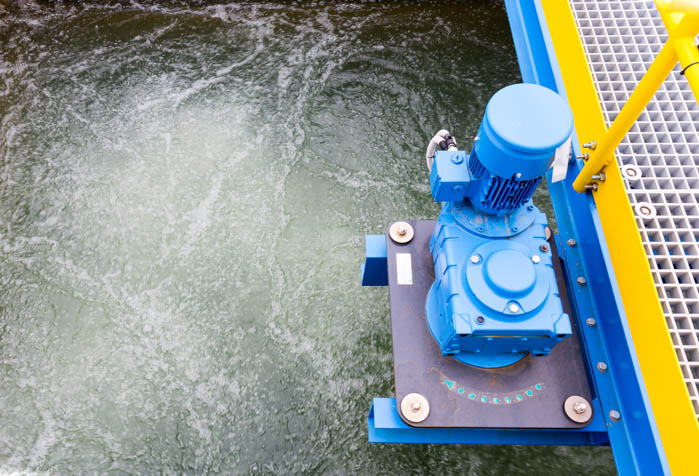

- Pretreatment and conditioning. Pretreatment is used to remove simple things from the wastewater stream that can be filtered or precipitated out, conditioning the water and reducing the suspended solids and materials that would otherwise scale and/or foul following treatment steps. Typically this treatment block consists of some type of clarifier and/or a reactor to precipitate out metals, hardness, and silica. Out of this process comes a liquid that is then filter-pressed into a solid, resulting in a solution much lower in suspended solids and without the ability to scale up concentration treatment.

- Phase-one concentration. Concentrating is usually done with membranes like reverse osmosis (RO), brine concentrators, or electrodialysis. These technologies take this stream and concentrate it down to a high salinity and pull out up to 60–80% of the water.

- Evaporation/crystallization. After the concentration step is complete, the next step is generating a solid, which is done through thermal processes or evaporation, where you evaporate all the water off, collect it, and reuse it. The leftover waste then goes from an evaporator to a crystallizer, which continues to boil off all the water until all the impurities in the water crystallize and are filtered out as a solid.

Again, the degree to which these steps are implemented in your specific ZLD system will vary depending on your facility’s individual needs. It is important to have a thorough wastewater treatability study done to be sure the contaminants present in your wastewater stream are dealt with accordingly.

In short, the specific contaminants, volume of those contaminants, and required system flow rate will all affect what technologies make up your ZLD system, and ultimately this will also affect the cost of it. For example, if your plant runs consistently at a lower flow rate, you’re usually looking at a lower capital cost for your ZLD treatment system. If your plant generally runs a greater flow in a shorter amount of time, your capital cost is usually higher for equipment.

Flow rates should always be factored into the ZLD treatment system cost, so be sure you measure this as efficiently as possible prior to requesting a quote in order to get an accurate cost estimate for your system. Sometimes inlet buffering tanks can be installed to minimize the peaks in flow and concentration of contaminants.

[Download our free zero liquid discharge e-book.]

Other important factors to consider when pricing a ZLD treatment system

- Up-front planning. Developing the concepts, designs, and regulatory requirements for your project is the first step to planning your ZLD treatment system. The cost of engineering for this type of project can typically run about 10–15% of the cost of the entire project and is usually phased in over the course of the project, with most of your investment being allocated to the facility’s general arrangement, mechanical, electrical, and civil design.

- Space requirements. When planning for a ZLD treatment system, the size of your system and your plant location will affect your cost. For example, if your plant is located in a place that is very expensive when it comes to space, you might want to aim for a smaller footprint, if possible.

- Installation rates. Another thing to keep in mind is the installation rates in your area. These sometimes also fluctuate by location, so be sure you’re aware of the cost to install the system and factor this into your budget. In areas where installation costs are high you may want to consider prepackaged modules versus build-in-place facilities.

- Level of system automation needed. When it comes to the level of automation you need for your ZLD treatment system, there are two options. The first is a higher level of automation where you won’t need an operator present for much of the time. With type of automation, you can eliminate much of the human error associated with running the plant, and although this option is more costly up front (an initial investment in more sophisticated PLC controls and instrumentation), the ongoing labor costs are less. The second option is a lower level of automation with less capital cost, but with added labor, this can end up costing you more in the long run. When deciding whether or not to invest in more costly controls, you need to consider what works for your company and staffing availabilities.

- Turnkey and prepackaged systems. If you are able to order your ZLD treatment system prepackaged, this will typically save you construction time at about the same cost or less. A benefit to having your system prepackaged is that the production facilities and fabrication shops that assemble your system are, more often than not, highly knowledgeable about the type of system they are manufacturing. This results in a quick and efficient fabrication versus build-in-place facilities. Sometimes when you hire a field crew, there is a bit of a learning curve that can add extra time and/or cost to a project. SAMCO specializes in these types of turnkey, prepackaged systems, and for more information about what we offer, you can visit our website here. Installation costs will vary, but typically range between 15–40% of the project cost, depending on the specifics of prepackaging and amount of site civil work needed.

- Shipping the system to your plant. When having your ZLD treatment system shipped to the plant, you usually want to factor in about 5–10% of the cost of the equipment for freight. This can vary widely depending upon the time of year you are purchasing your system in addition to where your plant is located in relation to the manufacturing facility. When you are looking to purchase your system, check with your manufacturer to see if there is a facility where the system can be constructed closer to you, if not on-site.

- Operation costs. Also keep in mind that particular technology packages cost a certain amount to purchase up front, but you need to also factor in system operating costs over time. For decisions like these, you need to weigh the pros and cons of initial versus long-term cost investment in addition to what works for your company and staff. You will likely want to look into having someone develop an operating cost analysis so your company can plan ahead for the operating cost over your wastewater treatment plant’s life cycle. This might help you consider whether or not you want to spend more on your system initially or over time. With ZLD systems, operational cost review is critical, especially for electrical power and steam-generating facilities. The cost of operations can change drastically based on the type of evaporator selected.

- Other possible costs and fees. When purchasing a ZLD wastewater treatment system, you might also want to keep in mind what other hidden costs and fees might be. For example: Will there be any taxes on the system or additional purchasing fees? What are your possible utility costs to the installation area? Will there be any environmental regulatory fees and/or permits? Any ongoing analytical compliance testing you need to pay for?

Also consider that there will be costs to treating the secondary waste produced by the system. With stringent environmental regulations, you will need to either treat the waste for hauling away or solidify with a filter press/evaporator and transport to third party disposal firm. You can learn more about SAMCO’s ZLD wastewater treatment systems on our website here.

Also be sure to ask your system manufacturer about options that might be cheaper to install. They might be able to shed some light on the more installation-friendly systems with suggestions on how to keep your costs to a minimum.

The bottom line

When it comes to treating your wastewater for ZLD, even though the treatment option and costs can be complex, all in all, you are looking at a system that can run upwards of $25 to $50 million at a flow rate of one to three thousand gallons per minute when you factor in all the needed equipment, engineering, design, installation, and startup. Smaller systems that run about one to 20 gallons per minute can cost between $250,000 to over $2 million.

The pretreatment is fairly inexpensive and is fairly similar to primary wastewater treatment. The membrane processes are a little more expensive, but they’re similar to the membrane processes used in water treatment and purification treatment. They are a bit more expensive because they are concentrating waste to yield higher recovery rates. The biggest expense will be on the evaporative and crystallization section. (On overall equipment cost, about 60–70% of the cost will go to evaporation/crystallization block. 30–40% on front-end pretreatment and RO. The bigger the system gets, the more these numbers will fluctuate.)

What Now?

SAMCO has over 40 years’ experience custom-designing and manufacturing these types of systems, so please feel free to reach out to us with your questions. For more information or to get in touch, contact us here to set up a consultation with an engineer or request a quote. We can walk you through the steps for developing the proper solution and realistic cost for your ZLD wastewater treatment system needs.

You might also be interested in reading more about wastewater in the following blog articles:

- 9 of the Best Industrial Wastewater Treatment Equipment Supply and Technology Companies

- What Is a Wastewater Treatability Study and How Does it Work?

- How Much Does a Wastewater Treatment System Cost? (Pricing, Factors, Etc.)

- The Importance of Wastewater Treatment for Your Facility: Is it Necessary?

- How to Choose the Best Wastewater Treatment System for Your Plant

- How Do You Know If An Industrial Facility Needs a Wastewater Treatment System?

How much do brine water treatment systems cost?

Costs for brine water treatment systems can vary significantly from one application to the next, but in general, high stream volumes, complex brine chemistry, and stringent purity specifications will all drive the cost of a brine treatment system upward. Here, we’ve offered some ballpark figures for costs associated with some common brine treatment setups.