What Are Reverse Osmosis and Nanofiltration and How Do They Work

Reverse osmosis and nanofiltration are often spoken about in unison as they are similar membrane technologies that solve a variety of process separation and filtration needs. The two technologies are being utilized more and more by industrial facilities looking to recycle and treat industrial wastewater for reuse and conservation. As water scarcity issues continue to increase, these technologies have become a long-term economical solution for avoiding astronomical discharge and water-usage fees in addition to serving other filtration requirements, such as process-water generation and product concentration.

If you are looking for a separation and/or filtration solution, you might be thinking RO/NF is a good fit. But what are reverse osmosis and nanofiltration, exactly, and how do they work?

This article will simplify these technological processes so you can get a better understanding of how they might be able to help your facility:

What is reverse osmosis?

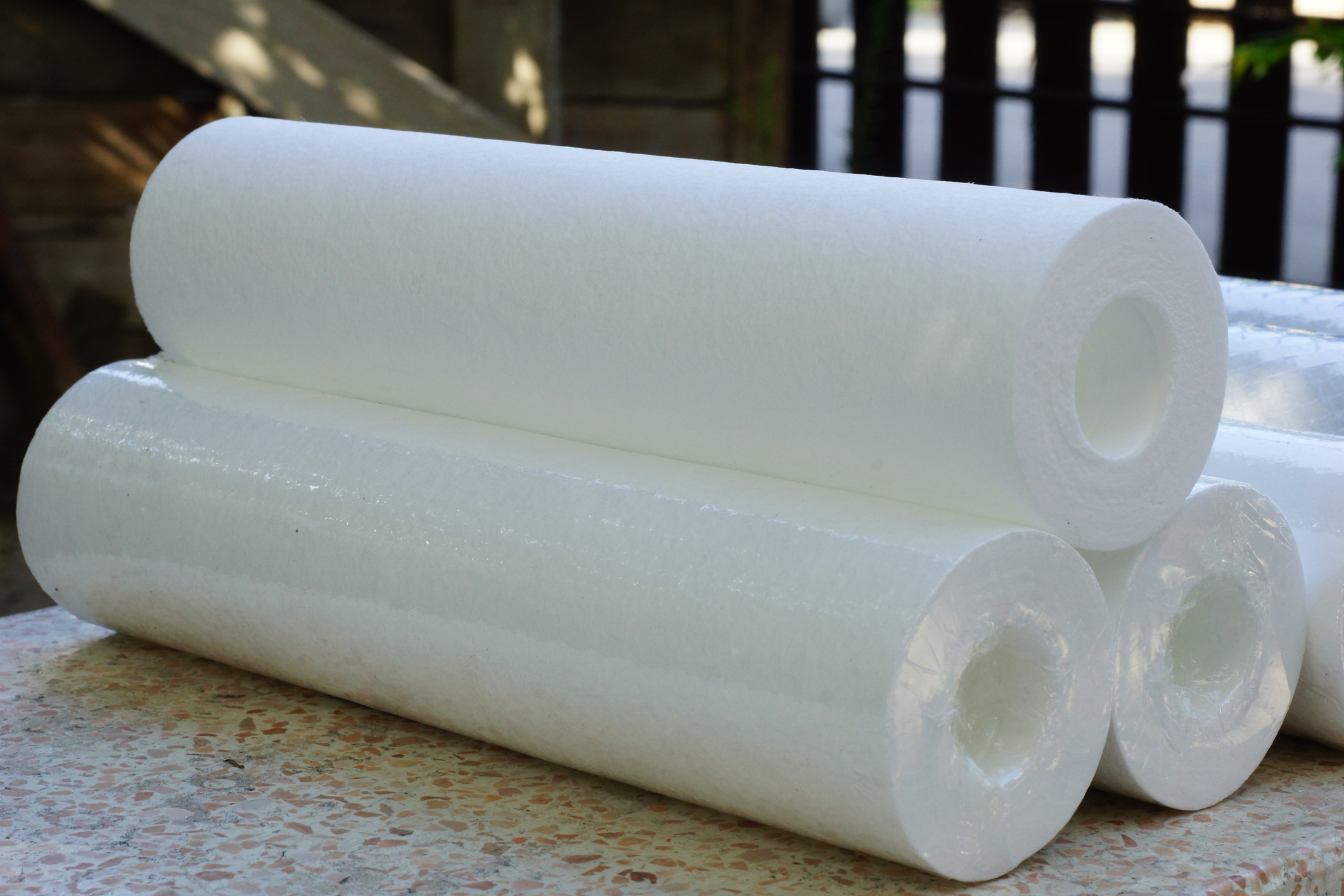

Reverse osmosis, also known as RO, is a membrane technology that uses a semipermeable medium to remove certain ions and particles from a liquid stream. RO removes contaminants based on their particle size and charge—generally anything that is 0.0001 µm or larger, including:

- bacteria

- calcium

- colloidal particles

- fluoride

- iron

- manganese

- organic material

- pyrogens

- salt

- viruses

Because of its filtration properties, RO is often used to:

- clean wastewater to acceptable effluent standards or for reuse

- concentrate solvents used in the food and beverage industry, such as whey

- create ultrapure process water streams, such as required in the microelectronics industry

- desalinate seawater or other brine solutions

- generate potable drinking water

RO is also the reverse process of osmosis, a phenomenon that occurs naturally when a lower-solute stream (with a higher-water concentration) migrates toward a higher-solute stream (with a lower-water concentration) through a semipermeable membrane to achieve concentrate equilibrium.

[Download our free RO/NF membrane system e-book.]

What is nanofiltration?

While RO and NF are both membrane technologies that uses a semipermeable medium to remove certain ions and particles from a liquid stream, they can be distinguished based on the size of particulates that each is able to remove. Comparatively, RO and NF are capable of removing finer contaminants than microfiltration and ultrafiltration, with applications including the removal of:

- hardness

- heavy metals

- nitrates

- organic macromolecules

- radionuclides

- sulfates

- total dissolved solids (TDS)

Nanofiltration, however, delivers slightly coarser filtration than RO, with the ability to remove particles as small as 0.002 to 0.005 μm in diameter, including pesticide compounds and organic macromolecules, while retaining minerals that RO would otherwise remove. Nanofiltration membranes are capable of removing larger divalent ions such as calcium sulfate, while allowing smaller monovalent ions such as sodium chloride to pass through.

Because of its filtration properties, nanofiltration is often used to:

- concentrate and demineralize valuable byproducts, such as metals from wastewater

- generate potable drinking water

- remove nitrates

- remove pesticides from ground or surface water

- soften water

How do they work?

As mentioned above, RO is the reverse of osmosis, which is a passive, naturally occurring process that happens without the use of energy. For example, if you were to place a semipermeable membrane in a tub of water then add salt to one side, the water would naturally migrate from the side without salt to the side of the semipermeable membrane where you added the salt to dilute the concentrated, salt-contaminated liquid until the two sides were equally dilute. You would end up with one side having a higher level of water, creating what is known as osmotic pressure. RO and NF function similarly, the difference being what size particulates are being filtered out.

With RO/NF, since you are removing contaminants from a high-solute liquid stream, energy larger than the naturally occurring osmotic pressure must be applied to force the solvent from the (highly concentrated solution) through the semipermeable membrane in the opposite direction than what would occur naturally and without force. This causes the permeate to pass through the semipermeable membrane while trapping and filtering out any contaminates larger than the pure water that passes through to the lower-pressure side.

The pressure required to push the solvent through the semipermeable membrane depends on the concentrate of solids. The more concentrated the stream is, the more pressure you need to apply to overcome the osmotic pressure and force the permeate (filtered water) through. This leaves you with a highly concentrated reject stream that is either used or discarded, depending on the separation/concentration needs of the facility.

Can SAMCO help?

SAMCO has over 40 years’ experience custom-designing and manufacturing RO/NF systems for a range of industries and solutions, so please feel free to reach out to us with your questions.

For more information or to get in touch, contact us here to set up a consultation with an engineer or request a quote. We can walk you through the steps for developing the proper solution and realistic cost for your RO/NF treatment system needs.

Head on over to our blog to learn more about industrial filtration and process separation technology. Some articles that might be of specific interest to you include:

- Does Your Facility Need a Reverse Osmosis or Nanofiltration System?

- How Do You Choose the Best Reverse Osmosis and Nanofiltration Membrane System for an Industrial Facility?

- Reverse Osmosis and Nanofiltration Membrane Filtration Systems: Common Problems and How to Fix Them

- What Are the Best Companies for Reverse Osmosis and Nanofiltration Membrane Systems?

- Reverse Osmosis vs Nanofiltration Membrane Process: What Is the Difference?